PRODUCT FLOW DESIGN

We design product flow systems for food manufacturers

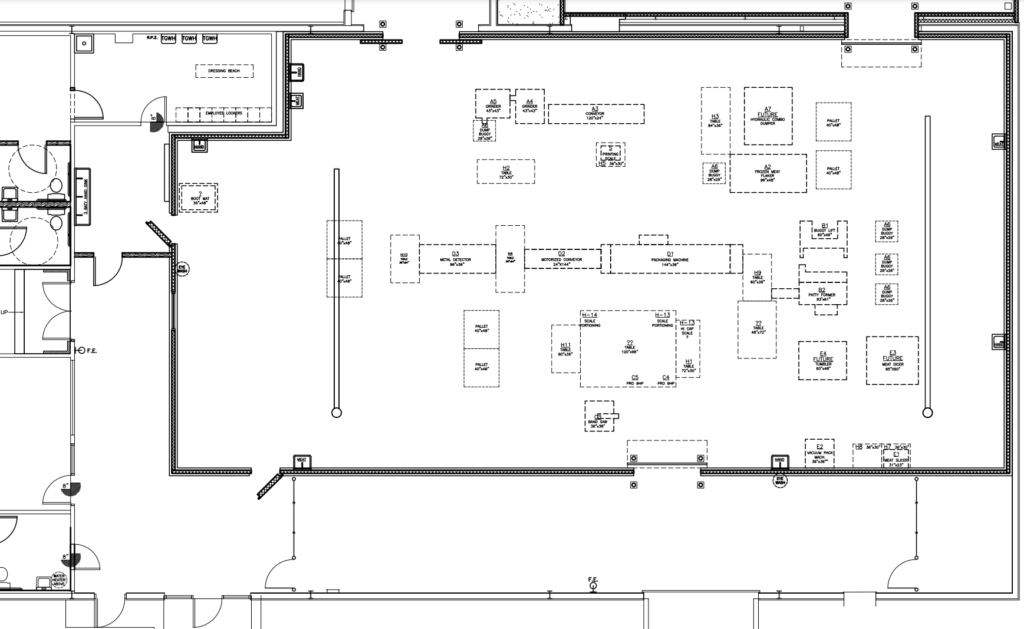

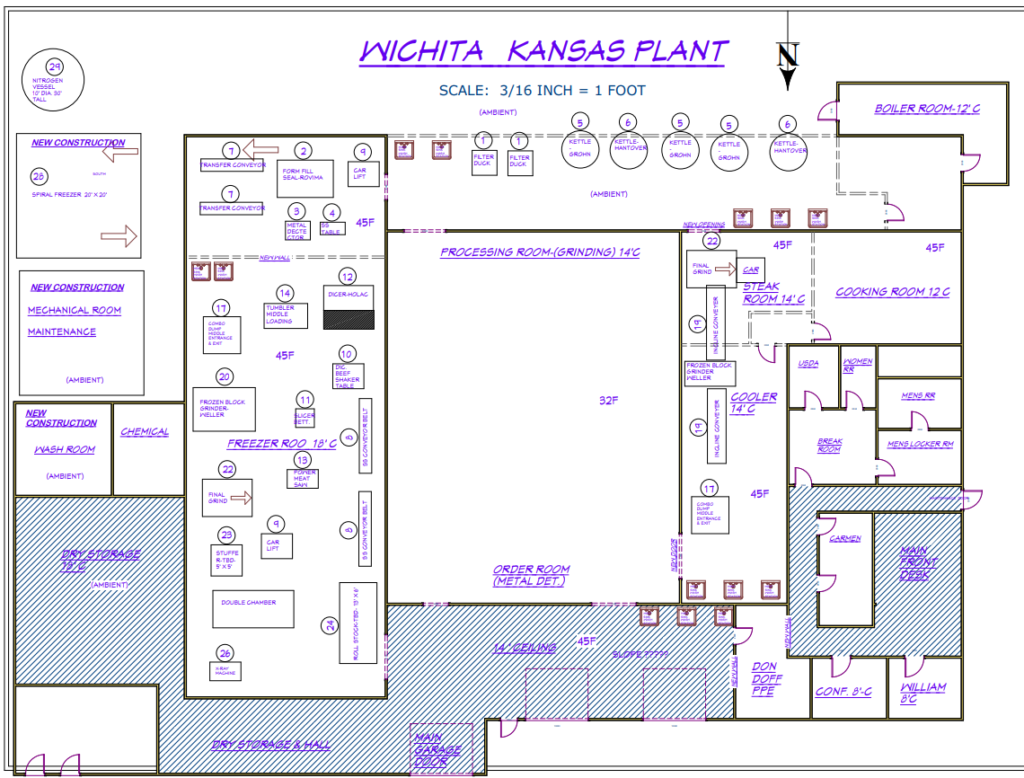

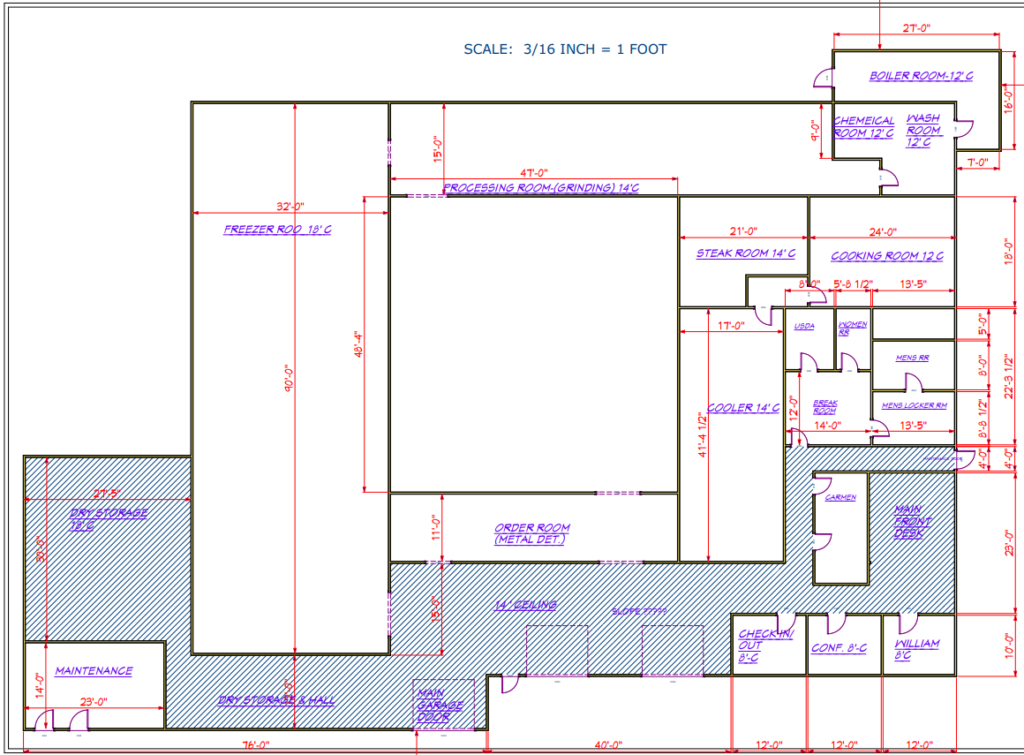

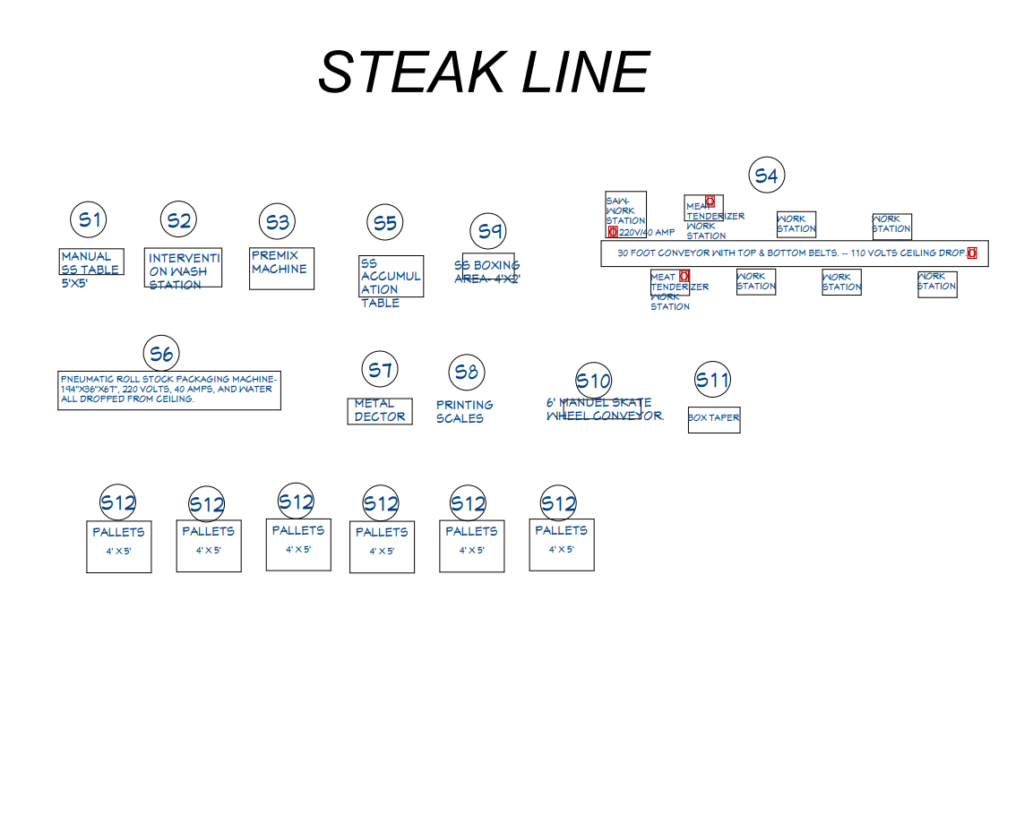

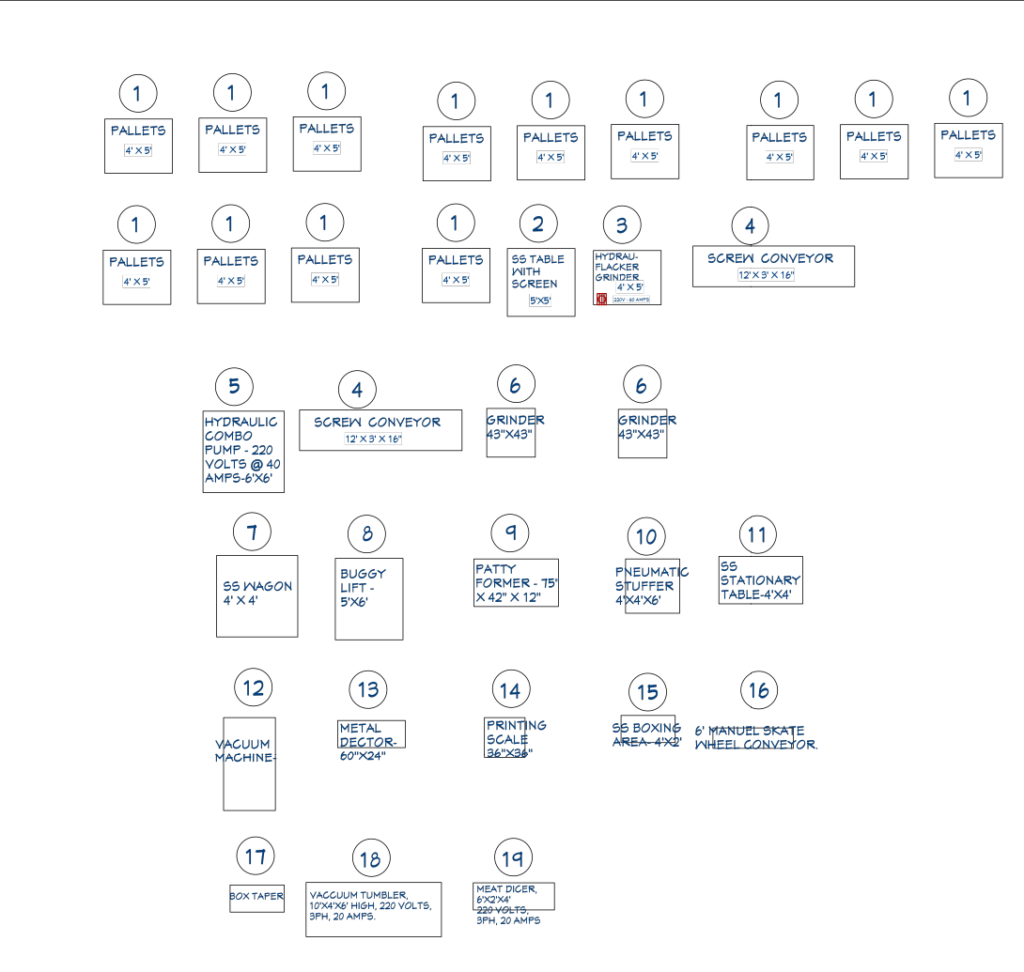

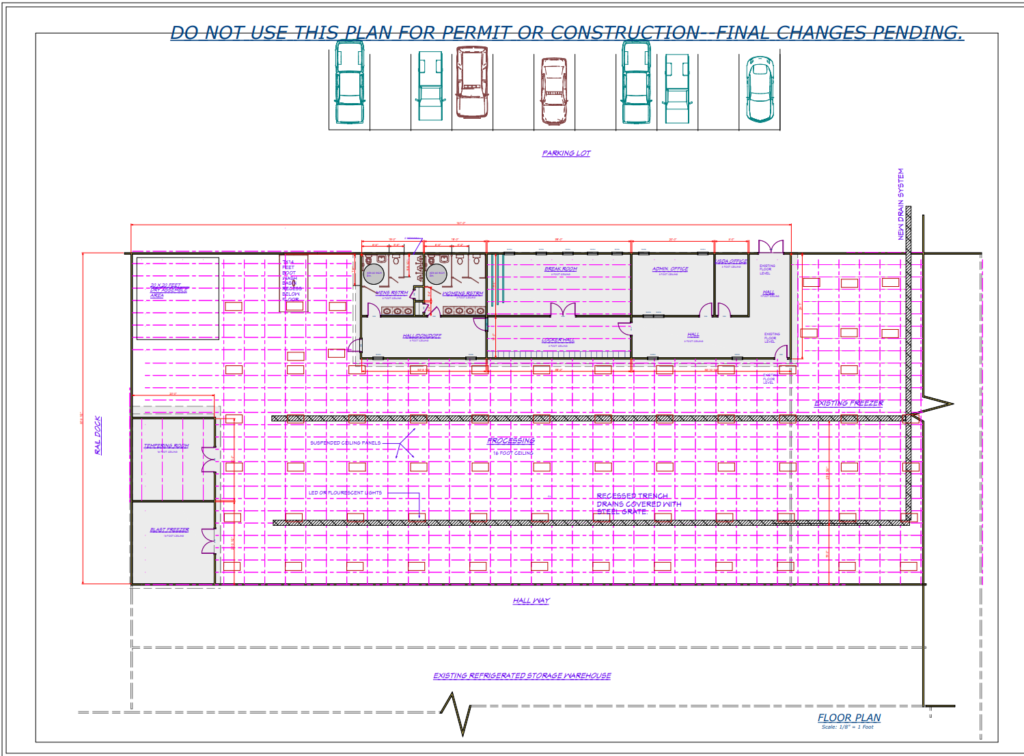

APS can design product that fits an existing facility, provide equipment layouts for new construction, or reduce labor through automation. We source equipment both new and used without the sellers knowledge of the purchaser and provide several options for each piece based on solely on the attributes and the value it brings to your production.

Our role in your expansion plans would be to design a process flow for you product that can increase capacity, reduce the demand for labor, and modernize your technology. We have designed layouts for installation in new construction or existing building dimensions. APS regularly reviews available real estate properties in the food processing industry. We can autonomously locate new, rebuilt and / or used equipment to fit your budget. Our equipment recommendations are often able to compare multiple options to offer you the best ‘value’ for your investment while considering numerous factors: cost, depreciation, labor, power, variability of options, sanitation, financing, service, parts availability and lead time. With a strong network of professionals in flooring, refrigeration, insulated panel installation, and drains, we are typically able to present scenarios to reduce cost and project timetables.

FOOD SUPPLY CHAIN SOURCING

A necessity to today’s food manufacturers and end- users, American Protein Services uses a network of professionals throughout the nation that provide us with available food processing capacities and specific product demands of food service, convenience stores, and retail grocers. Most recently, we have been focused on contracting for spot products needs and finding reliable secondary suppliers.

APS is in constant communication with manufacturers trying to fill capacity or grow their business. At the same time, many of our clients are in the restaurant and grocery store business. Based on years of experience, we see a long term continuation of manufacturers expanding, automating, modernizing and in general planning to put more and new products in to the supply chain. Interestingly, we have been very active with food service and retail grocers who are looking at adding secondary suppliers and or being forced to find new sources for products as some of the larger manufacturers cut item sku’s due to lack of labor or for optimization of processes. Our role is to constantly make ourselves aware of industry conditions, interact through various meat associations, and continue to expand our network of professionals.